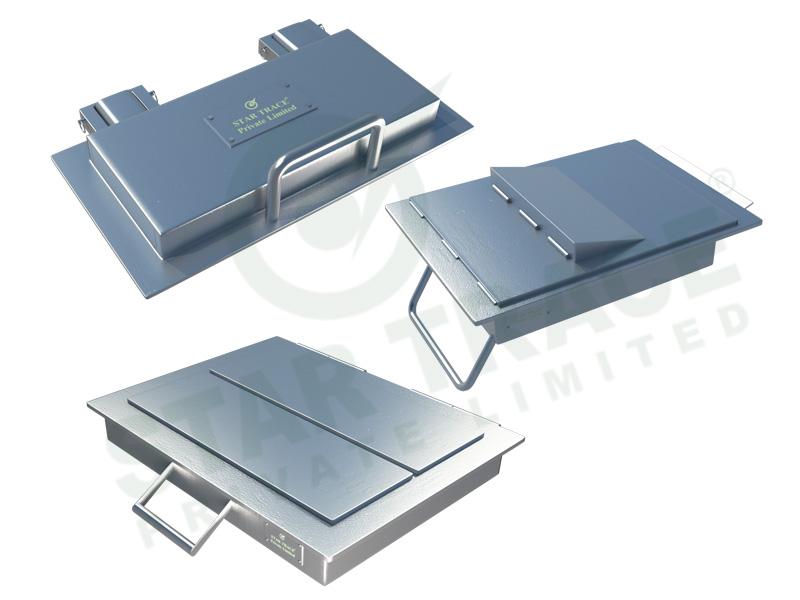

Magnetic Equipments- Plate Magnets

We are well-reputed manufacturer and supplier of brilliant quality stainless steel plate magnets using refined quality raw materials to ensure both quality of plate magnets and customer's satisfaction. Our company offers these permanent plate magnets at customers-budget friendly prices. We have highly qualified and experienced professionals who hold specialization the domain of Plate Magnets manufacturing industry. These plate magnets are designed for easy installation in your granulator's feed tray, and are an economical way to prevent tramp metal from damaging your equipment and contaminating your product.

Star Trace offers a wide spectrum of Industrial Magnetic Plate that are designed to suite varied dimensions and industries. With over quarter of a century experience as manufacturers and suppliers we have been clearly leading in the sale of industrial magnetic plate. The Plate Magnet is a food grade magnet used widely in processing. The industrial magnetic plate comes into direct contact with edible items in industrial production line & it's mandatory that standards are adhered. The industrial plate magnet is intended to trap ferrous elements that are contaminants in assembly; so they are stationed either at the bottom of a chute or on top of a conveyor to function effectively.

- Low profile design for smooth product flow over the face of the magnets

- Easy 4 bolt installation with mounting hardware (included)

FLUSH FACE

Flush Face Star Trace Plate Magnets deliver optimum tramp metal separation performance when used in above-the-flow chute or belt application. When installed over the material flow, the powerful Flush Face plate magnets deliver continuous magnetic protection for down stream processing equipment by lifting ferrous tramp out of the product flow stream.

EXPOSED POLE

Star Trace's Exposed Pole plate Magnets are engineered to deliver high performance tramp metal separation in low volume applications. These applications are for below-the flow installations where the product flows over the plate magnets face.

SPOUT MAGNETS

Star Trace diverter Spout Plate Magnets provide maximum ferrous tramp metal separation in high volume chute applications where wash-off can be a problem. Spot Plate Magnets employ a primary diverter to prevent tramp metal "wash-off". A secondary diverter reduces product degradation by ramping the product over the downstream chute edge.

SELF-CLEANING SPOUT MAGNETS

Star Trace's Self - Cleaning Spout Plate Magnets provide ferrous tramp metal removal, in chute applications, with remote cleaning. Air cylinders are used to swing plate magnets and spout face away from chute. While the cylinder is moving the Self-Cleaning Spout Magnets, the spout face stops. separating it from the magnets. Once the plate magnets are separated from the spout face the collected tramp iron is discaded. Air cylinders return both plate magnets and spout face back to operating position.

RARE EARTH (NEODYMIUM) SPOUT MAGNETS

Fine particle size separation is now available in a plate magnets. This plate magnets are substantially stronger than conventional plate magnets. Located in chutes, this rare earth ,plate magnets can capture weakly magnetic iron in dry or wet product flows. This plate magnets features two liquid tight diverters to prevent captured tramp iron wash-off. Manufactured in two different strengths and in widths to match your chute.

FLAT CONVEYOR PLATE MAGNETS

Ideal for wide conveyors, this plate magnets can be manufactured to match your conveyor width. Available in several thickness and strengths to effectively remove tramp metal that has fallen on the conveyor. Located prior to packaging machinery. this plate magnets are currently being used for single layer products such as: cookies, crackers, chips, pretzels, textiles, fiberglass, etc. This plate magnets measures 6-3/16" long, with the product flow, by 1-5/16" thick. Manufactured in widths to match your conveyor.

Construction and working of Industrial Plate Magnet:

Plate magnet is simple in making where its face is made of a square or rectangular plate beneath it is a rare earth magnet. This set up comes with variations in length, breath and thickness to match exact requirements. We as seasoned manufacturers and suppliers go a step ahead and serve custom made plate magnets to satisfy our client base globally and in India.

The placement of industrial plate magnet is below the course, as iron particles settle down due to weight. Though this is considered as the best location for magnetic influence, placing the plate magnet above the flowing raw material is also viable and effective, when the closest possible position is maintained. A times when the gutters are at angles of 45 degrees the magnetic plate is fixed in the angular slant and installation of two to three industrial magnetic plates is suggested depending upon the level of contamination expected by the manufacturers or suppliers. Self-cleaning industrial magnetic plates are available for sale & this is achieved when the magnetic field is pulled away from the plate.

To have a taste of perfection and uninterrupted work flow associate with us over a sale as experienced by our esteemed clients in India and globally. We are sure to impress you in the first sale!!

Our Other Links