Magnetic Equipments- Permanent Suspension Magnet

PERMANENT SUSPENSION MAGNET

Permanent Suspension Magnet is engineered for use in high volume and deep burden applications. Their primary advantages are their "deep reach" and the ability to be turned on and off. Mounted over a vibratory bed or belt conveyor, these permanent suspension magnet set the industry standard for strength.

Permanent Suspension Electro Magnet consisting of aluminum or copper wound coils immersed in a transformer oil (for prevention of overheating or shorting) or air-cooled for extreme or dusty environments.All permanent suspension electro magnet comes along with control panel. Operating heights up to 150 mm to 450 mm are available. Manually cleaned permanent suspension magnet can be supplied with a stripper mechanism. No power consumption, virtually maintenance free.

The ERBM Series permanent suspension magnet is a powerful oil-cooled electromagnetic plate magnet, suspended over the conveyed product stream. The permanent suspension should be located in an area on the production line that allows easy access for proper maintenance of the permanent suspension and it should be operated in an area where no integral parts of the conveying system can become magnetized; such as idler rollers, pulleys or belt support plates.

Manual Clean (MC) units must be periodically turned off in order to discharge iron accumulated on the face of the permanent suspension. They are suitable for applications where only occasional tramp iron is expected. These permanent suspension is usually suspended from a travelling trolley so that they can be swung clear of the conveyor before the iron is released.

Self-Clean (SC) Permanent Suspended Electro Magnet provide continuous, automatic removal of tramp iron and feature a heavy-duty belt, a channel frame for supporting the pulleys, adjustable belt take-up and drive. They are recommended where a large amount of tramp iron is expected or where there may be limited access to the permanent suspension for cleaning purposes.

- Rugged-all-welded construction can efficiently prevent the coil from erosion of moisture, dust and harmful gas. Good environment and climate suitability, safe and reliable in operation and convenient maintenance.

- The magnetic circuit is designed in optimization with deeper permeability,and its geometrical figure in the space magnetic field shaped semi-sphere so that will produce much stronger magnetic force compared with the other wares.

- Field winding coil treated by vacuum desiccation and filled with special packing material to improve its mechanical and electrical performances and keep a long service life.

- Easy to form a complete set with other equipments to meet the different requirements under all kinds of circumstances.The relevant commutating equipments have complete functions available.

- Stainless steel wear plates

- Turnbuckles

- Volt Meters

- Amp meters

- Line fuses

- Disconnect switch

The following are the features of Permanent Suspension Magnet:

- Non-combustible coolant.

- Internal expansion tank.

- Insulated copper/Aluminium coils.

- Heavy duty impact plate.

- Stainless steel angled cleats.

- Steel dust enclosures for permanent suspension magnet installations in dusty locations.

- Rugged-all-welded construction can efficiently prevent the coil from erosion of moisture, dust and harmful gas. Good environment and climate suitability, safe and reliable in operation and convenient maintenance.

- The magnetic circuit is designed in optimization with deeper permeability,and its geometrical figure in the space magnetic field shaped semi-sphere so that will produce much stronger magnetic force compared with the other wares.

- Field winding coil treated by vacuum desiccation and filled with special packing material to improve its mechanical and electrical performances and keep a long service life.

- Easy to form a complete set with other equipments to meet the different requirements under all kinds of circumstances.The relevant commutating equipments have complete functions available.

PERMANENT SUSPENSION MAGNET APPLICATIONS

Reliable Tramp Iron Removal from Fast-Moving Conveyors in Processing Industries for:

- Purification of Product or Ingredient for Higher-Quality End Products (e.g., foundry sand, glass cullet, grain, food products and chemicals).

- Protection of Processing Equipment (e.g., crushers, pulverizers, conveyor belts and screens).

- Reclamation of Ferrous or Non-Ferrous Material (e.g., open hearth and blast furnace slag, incinerators and garbage plants).

- Salvage of Valuable Items (e.g., tools, cutter bits and machinery parts).

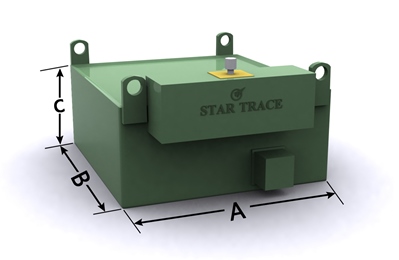

PERMANENT SUSPENSION MAGNET SPECIFICATION

| STR Model | Magnet Dimensions mm | Magnet Height mm | Magnet Voltage VDC | Magnet Wattage | Approx Weight Kgs |

| STR 241 | 600 X 600 | 550 | 115 | 1650 | 430 |

| STR 301 | 750 X 750 | 650 | 115 | 2700 | 700 |

| STR 361 | 900 X 900 | 500 | 115 | 3800 | 1050 |

| STR 422 | 1050 X 1050 | 550 | 230 | 5000 | 1600 |

| STR 482 | 1200 X 1200 | 600 | 230 | 6600 | 2250 |

| STR 542 | 1350 X 1350 | 650 | 230 | 8000 | 3150 |

| STR 602 | 1500 X 1500 | 750 | 230 | 10000 | 4000 |

| STR 662 | 1650 X 1650 | 800 | 230 | 12250 | 5200 |

| STR 722 | 1800 X 1800 | 800 | 230 | 14500 | 7250 |

| STR 782 | 2000 X 2000 | 900 | 230 | 17000 | 9100 |

Our Other Links